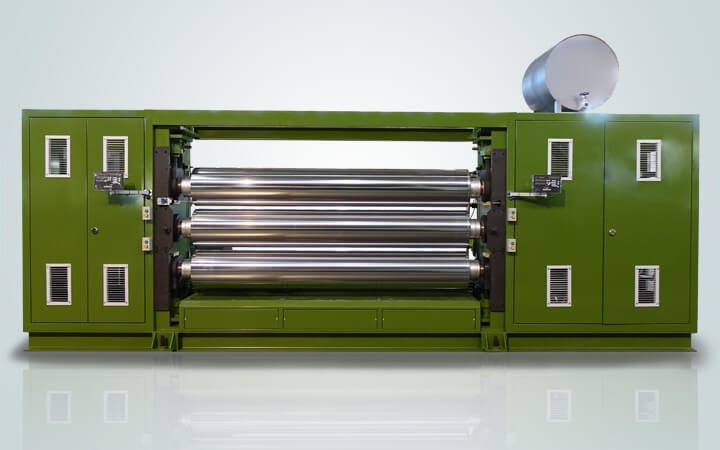

Three Roll Calender Machine

Products

Three Roll Hot Calender Machine

The 3 roll hot calender machine is generally used in the latter part of the needle machine, which is composed of three cylindrical rollers with a diameter of 400 to 600 mm. The roller is filled with high-quality heat transfer medium fluid, and the heat energy is transferred to the surface of the roller through the pumping cycle and the roller rolling, and then the low-melting fiber in the product is melted and heated by the high temperature of the wheel surface and the high pressure between the rollers. Bonding and heat setting, on the one hand, accurately control the thickness of the product.

Chao Chiun ensures the uniformity of the thickness of the non-woven fabric based on experience and innovative technology. Chao Chiun 3 roll calender machine is equipped with a specific temperature adjustment device, also equipped with a displacement detection device, which can adjust the speed of the calender by itself. It allows you to set the machine processing according to different technical requirements.

Technical parameters

| Working width | 1000-6000mm |

| Production speed | 5-50M/min |

| Max working temp | 250℃ |

| Heating systems | Electrical heating Thermal conductive oil circulation |

| Working pressure | 10kg/cm |

| Roll surface | Chromium plating |

| Adjusting of the roll distance | Electric Hydraulic cylinder |